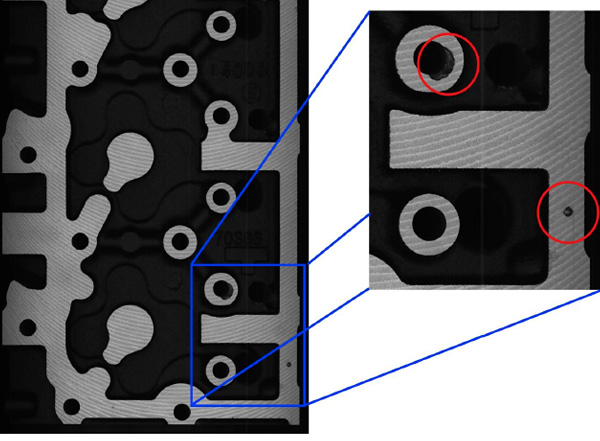

Casting pores detection

- Flexible solution for detection of casting pores.

- Can be complemented with additional measurements.

Unwanted pores often emerge when casting metal. After machining, pores are sometimes visible in critical areas. A vision system can detect and sort out defect products, thereby replacing exhaustive manual inspections.

Mabema provides flexible solutions for detection of casting pores. Either as a standalone unit served by robot or as an inline inspection unit. The system can be expanded to verify additional features, such as positions, diameters and presence of holes.

Image above shows a standalone inspection system for detection of casting pores. This unit is served by robot.

- Smallest detectable pore: 0,5 x 0,5 mm2 or smaller (depending on field of view).

- Field of view: Depending on application.

- Cycle time: Depending of object size. Scan rate: approx. 0,2 m/s.

- Communication: ProfiNet, Ethernet/IP, TCP/IP and digital I/O:s.

- Measures: H 1000, b 1200, d 1000 mm (also depending on object size).

- Weight: approx. 250 kg.

Guidance: Vision

Get guidance on which Vision product is best suited by calling +46 (0)73-515 37 13 or e-mail us.

Training: RobotVision

During a full day, you will get to know FINDER 3D as well as practical exercises for a basic understanding and management.