We proudly introduce the Mabema AAI 3.0, an improved and more superior inspection machine for ammunition. The Mabema AAI 3.0 increases manufacturers process control, quality and profitability by providing cost effective and reliable quality inspections. With a fixed throughput rate of 120 parts per minute, world leading vision technology and high-resolution cameras the Mabema AAI 3.0 carries out a full inspection of small arms cases, cartridges and bullets.

Since 2014 Mabema has delivered eight machines for automated ammunition inspection to both Swedish and international customers. Based on the feedback from our customers and updates in the machine vision industry we have developed the Mabema AAI 3.0 – a more superior machine for inspection and measuring of small arms cases, cartridges and bullets.

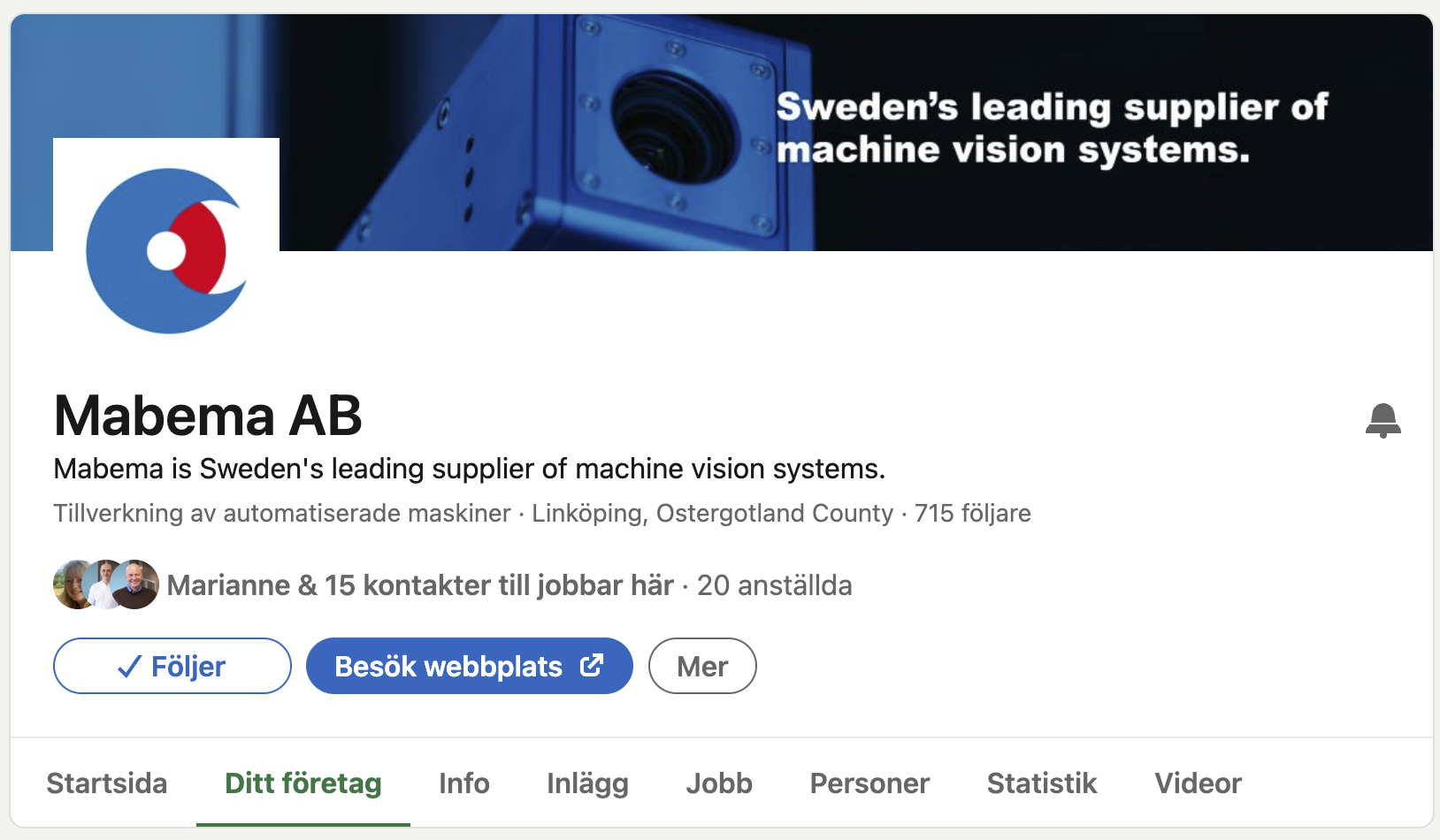

Our new automated inspection machine carries out high precision measurement and inspection of all critical features of the part such as the extractor groove, primer, bullet or mouth as well as both 2D- and 3D inspections of the body. Some examples of defects that the machine detects are wrinkles, scratches, dents along with various defects on the extractor groove, primer and bottom stamp. One of the key benefits of the Mabema AAI 3.0 is the surface inspection. It is carried out with line scan cameras and special LED-lights that enables the machine to measure and sort out scratches, wrinkles and especially soft dents on the body.

The Mabema AAI 3.0 has a fixed throughput rate of 120 parts per minute, which is considerably faster than the earlier versions of the machine. The parts travel through the machine on a conveyor belt which results in less stops and higher reliability than before. Defect parts are blown out after each inspection station with the help of compressed air. This makes it easier to organize the parts depending on the defect category.

This January we delivered the first Mabema AAI 3.0 to an international customer and a few weeks ago the second machine was delivered to a customer in Sweden. At the time of writing we are building the third and fourth machine which are to be delivered to both new and existing US customers.

Before the second Mabema AAI 3.0 was sent off to our customer we took the opportunity to record a video of it. The result became an introduction of our new automated ammunition inspection machine, the Mabema AAI 3.0.

Video from 2023.